Product

All categories

Hydroponic infrared method

Hydroponic infrared method(reference standard GB/T 19276.2-2013 Determination of final aerobic biodecomposition capacity of materials in water-based culture solution using the method of measuring released carbon dioxide) :

One Experimental purpose

1. Meet the test standards of GB/T19276.2-2003;

2. Meet the test standards of GB/T33616-2017;

3. Meet the test requirements of GB/T40612-2021;

4. Meet the test requirements of GB/T40367-2021;

5. Meet the ISO14852-1999 testing standards;

6. Meet the testing standards of ISO19679-2020;

7. Can be used for activated sludge biodegradation detection;

8. Can be used for bio-based biodegradability detection;

Second, experimental principle

This experiment system simulates the process of biodegradation of bio-based materials under aerobic hydroponics. In the aerobic hydroponic environment, microorganisms consume oxygen and produce carbon dioxide, water and other inorganic substances. The generated carbon dioxide is monitored in real time by high-precision infrared sensor, and the real-time concentration of detected carbon dioxide is integrated with the flow rate and time, so as to calculate the carbon dioxide release from the biodegradation of the sample. The biodegradation rate is the percentage of the carbon dioxide released by the sample biodegradation and its theoretical carbon dioxide release.

Third, experimental materials

1. Distilled water

2. KH2PO4(no water)

3. K2HPO4(no water)

4. Na2HPO4·2H2O

5. NH4CI

6. MgSO4·2H2O

7. CaCI2·2H2O

8. FeCI3·6H2O

9. CuSO4·5H2O

10. Cellulose

11. Urea

12. Sodium lime

13. Compost

4. Experimental steps

1. Instrument preparation

1) Place the decarbonization bottle, reaction bottle, condensation bottle and dehumidification bottle in the corresponding position, and connect the hose.

2) Open the instrument power supply, open the ventilation system, infrared detection system, temperature control system; Check whether the air tightness of the reaction system is normal; Check whether the infrared detection data is within the normal range; Check that the temperature is maintained at a constant temperature.

2. Prepare the culture medium

1) Inorganic salt solution A constant volume to 1000ml:

KH2PO4(anhydrous) 8.5g

K2HPO 4(anhydrous) 21.75g

Na2HPO4·2H2O 33.4g

NH4CI: 0.5g

2) Inorganic salt solution B: Dissolve MgSO4·7H2O 22.5g in water at a constant volume of 1000ml;

3) Inorganic salt solution C: Dissolve CaCI2·2H2O 36.4g in water with a constant volume of 1000ml;

4) Inorganic salt solution D: Dissolve FeCI3·6H2O 0.25g in water with a constant volume of 1000ml;

5) Solution E: Take 30ml solution A, 3ml solution B, 3ml solution C, 3ml solution D, and the volume is fixed to 3000ml

The self-made compost of Tomorgan was mixed with solution E and incubated for a period of time, and the filtrate was taken.

3. Add experimental materials

1) Add sodium lime to decarbonized bottle.

2) Add the color-changing silicone to the dehumidifier bottle.

4. Sample addition

1) 300ml culture solution and 2g cellulose were added into the reaction bottle as the positive control group

2) 300ml culture solution and 2g samples were added into the reaction bottle as the experimental group

3) Connect the reaction system to check the air tightness.

5, adjust the instrument parameters

1) Adjust the flow rate of each channel to 100ml/min.

2) Clear the accumulated data of each channel and start the experimental cumulative data.

6. Maintain and observe data regularly

After the experiment began, it was observed every day whether there was any abnormality in the experimental equipment and whether the experimental data growth was in line with the expectation.

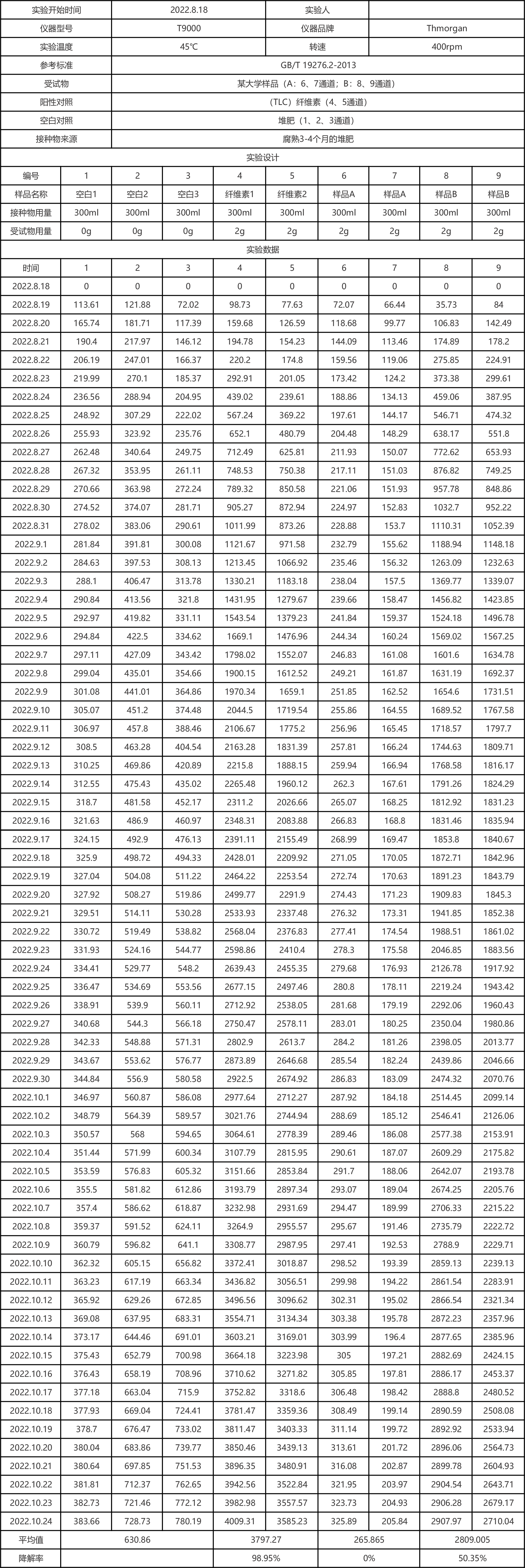

Five T9000 degradation experiment record report

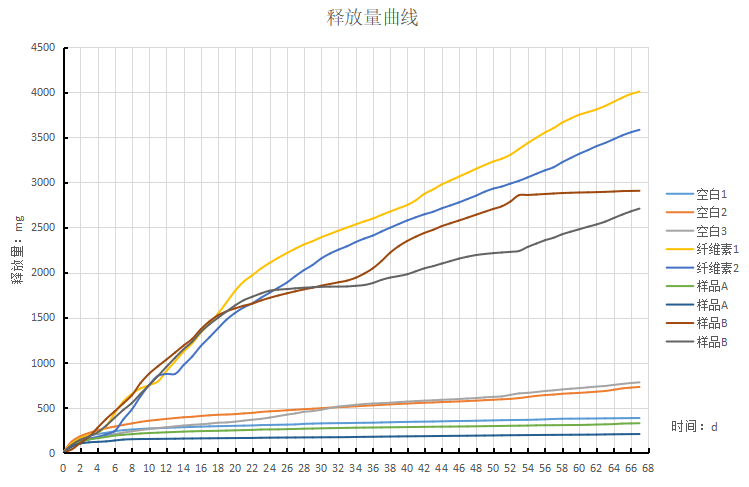

Six carbon dioxide release curves:

Conclusion:

1. This experiment started on August 18, 2022 and lasted for 67 days until the report date.

2. The biodegradation rate of cellulose reached 98.95% within 67 days; Over 67 days, the average CO2 release in the blank group was 630.86 mg.

3. The degradation rate of cellulose continued to increase, with little difference among parallel controls.

4. The biodegradation rate of sample A was 0% within 67 days, and the degradation rate was slow and inhibited. The biodegradation rate of sample B was 50.35%.