Practical Composting Technology

Practical Composting Technology

1. Introduction to composting process

Organic fertilizer fermentation process is an aerobic microbial fermentation process, which can treat breeding wastes including pig manure, cow manure, chicken manure, sheep manure, paper industry waste, garden shears and sludge, etc., to achieve the purpose of turning waste into treasure. This process improves the pile temperature quickly and shortens the compost fermentation time. After treatment, the number of beneficial microorganisms in the finished organic fertilizer is high, the appearance and color of the product are good, odorless, and the fast-acting and full amount of nutrients is high.

Second, the principle of process design

Design principles include environmental protection, economy, safety, resource utilization and harmlessness; No waste gas, waste water and waste residue are discharged to the outside world during the treatment process; Livestock and poultry manure is completely recycled, and the resource-based organic fertilizer products reach the national NY525-2002 quality standard; The removal rate of organic fertilizer pest eggs is more than 99%; To achieve the requirements of reasonable equipment selection, reliable use, high efficiency, energy saving and safety, organic fertilizer products can be converted into considerable direct economic benefits after treatment. In accordance with the requirements of national quality standards, the design and production of technology, civil engineering, products and other projects are carried out to ensure the safety of personnel.

3. Description of simple composting process

1. Composting scale and equipment

The composting line includes a simple fermentation shed and a small pulverizer.

Design scale: annual processing of livestock and poultry manure and other organic materials 1000 tons, annual output of organic materials 500 tons.

2. Simple composting process flow chart

After simple pretreatment of organic materials such as livestock and poultry manure, enter the simple fermentation shed that can protect from rain and wind to adjust the C/N ratio, humidity, pH and pile height of the compost materials, and then add organic fertilizer fermentation bacteria that can accelerate the decomposition of the compost materials and promote the compost fermentation for compost fermentation; The use of manual compost to pound, enhance the aerating effect, conducive to the growth of microorganisms, adjust the time and frequency of tipping to control the compost temperature, kill harmful bacteria and insect eggs, promote the growth of beneficial microorganisms and inhibit the volatilization of effective nutrients, achieve the purpose of controlling the quality of fertilizer products, and finally ensure that the products meet the national standards of organic fertilizer products through analysis and inspection.

This process is also suitable for composting near the vegetable field of the farmer's greenhouse, but the compost floor is required to be flat and have a certain hardness in order to overturn, and plastic film is required.

Simple composting process flow chart

3. Compost manual tipping regulation

The control C/N ratio is 25:1~30:1, the pH value is 6.5~7.0, the moisture is about 55%, and the stack height is about 60~100 cm, the temperature starts quickly, the fermentation effect is good, and the rot degree is good.

Use reasonable tipping frequency to control the compost aeration and temperature, so that the composting process efficiency is accelerated, before the stacking temperature does not reach 55 °C, do not carry out stacking, so that the stacking temperature can quickly rise to above 55 °C, but when the moisture of the fermentation material is above 60% or the composting temperature does not reach more than 2 °C after 50 days after the start of fermentation, it must be immediately turned over to increase the oxygen content in the stack and promote the rapid growth of microorganisms, so that the fermentation can proceed smoothly. When the stacking temperature rises above 55 °C, do not pound, carry out three consecutive days of stuffy pile, in order to kill Enterobacter faecali and roundworm eggs and other harmful pathogenic microorganisms and eggs, and then pound every two days until the compost temperature is constant, when the temperature exceeds 70 °C, it is necessary to immediately pound, eliminate the inhibition of microbial growth by high temperature, thereby promoting the activity of a large number of medium temperature bacteria and accelerating the process of composting. With the fermentation, the compost temperature will naturally drop to about 30 °C, the moisture will drop to about 20%, at this time the stacking should be stopped to end the fermentation, the whole fermentation cycle is 15~20 days.

In the process of stacking, it is necessary to achieve adjustment, uniformity and crushing, among which, adjustment is to intermodulate the original upper part and the lower part of the stack to achieve the purpose of full fermentation; Uniformity is to mix the part of the raw materials in the stack that is not evenly mixed again; Crushing is the crushing of the lumpy fermentation formed during the fermentation process.

The above process regulation is suitable for composting near the vegetable field of the farmer's greenhouse.

四、机械堆肥工艺说明

1、堆肥规模和设备

The composting production line includes fermentation silo, tipping machine, shovel, pulverizer, screening machine, small cart, product crawler conveyor and other equipment.

2. Composting process and flow chart

After simple pretreatment of livestock and poultry manure, it is put into the compost fermentation bin or plastic greenhouse fermentation tank to adjust the C/N ratio, humidity, pH and pile height of the compost material, and then add organic fertilizer fermentation bacteria that can accelerate the decomposition of the compost material and promote compost fermentation for compost fermentation. The use of special tipping equipment to pound the compost, enhance the aerating effect, conducive to the growth of microorganisms, adjust the time and frequency of tipping to control the compost temperature, kill harmful bacteria and insect eggs, promote the growth of beneficial microorganisms and inhibit the volatilization of effective nutrients, achieve the purpose of controlling the quality of fertilizer products, and finally ensure that the products meet the national standards of organic fertilizer products through analysis and inspection.

Mechanical composting process flow chart

3. Composting machinery tipping control

The control C/N ratio is 25:1~30:1, the pH value is 6.5~7.0, the moisture is about 55%, and the stack height is about 100~120 cm, the temperature starts quickly, the fermentation effect is good, and the rot degree is good.

Use reasonable tipping frequency to control the compost aeration and temperature, so that the composting process efficiency is accelerated, before the stacking temperature does not reach 55 °C, do not carry out stacking, so that the stacking temperature can quickly rise to above 55 °C, but when the moisture of the fermentation material is above 60% or the composting temperature does not reach more than 2 °C after 50 days after the start of fermentation, it must be immediately turned over to increase the oxygen content in the stack and promote the rapid growth of microorganisms, so that the fermentation can proceed smoothly. When the temperature of the stack rises above 55 °C, no pounding is carried out, and the pile is stuffy for three consecutive days to facilitate the killing of harmful pathogenic microorganisms and eggs such as Enterobacter faecalia and roundworm eggs, and then mechanically pound once a day. With the fermentation, the compost temperature will naturally drop to about 30 °C, the moisture will drop to about 20%, at this time the stacking should be stopped to end the fermentation, the whole fermentation cycle is 15~20 days.

4. Process equipment

(1) Arched fermentation silo

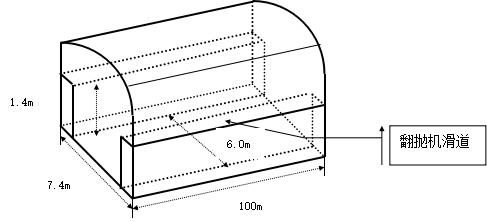

Schematic diagram of the arched fermentation silo

each fermentation silo; The length of the warehouse is 50-100m, the width is 6.0m, and the composting and fermentation height of the material is about 1.2m.

The annual output of 4,<> tons of organic fertilizer arched fermentation silo

(2) Fermentation tipping machine

The fermentation tipping machine should be widely used for the fermentation and throwing of organic wastes such as livestock and poultry manure, residue, crop straw, sludge, and urban waste. A tipping machine can throw 3~4 cubic meters of livestock and poultry manure in 400~450 hours, which is equivalent to the workload of 50 workers manually pounding, and can work in a greenhouse with 3~4 fermentation tanks 60~80 meters long, 1.9~2 meters wide and 1.3 meters deep. During the tipping process, the tipping machine can fully contact the material with the air, which supplements the oxygen required for the fermentation process. The material with the high temperature fermentation, the water is required to gradually dissipate, because the material is fully exposed to the air when throwing, the water can be quickly evaporated for many times, and the moisture content of organic fertilizer can be effectively reduced without drying. In the process of tipping, the tipping machine can realize the mixing and mixing of materials, mixing and crushing, flying and lifting, and can realize uninterrupted continuous production, and each time the tipping can produce a batch of finished products and enter a batch of raw materials.

Crawler fermentation tipping machine Mobile fermentation tipping machine

(3) Crusher and sieving machine

Fermentation rotten compost needs to be crushed with a pulverizer, packaging and fertilizer application, for materials that cannot be crushed and affect the appearance of materials need to be screened with a screening machine.