GB/T19277.1

GB/T19277.1

First, the purpose of the experiment

Under the conditions of intense aerobic composting, the final aerobic biodecomposition capacity and mass loss of the experimental materials were determined, and the degree of disintegration of the experimental materials was determined.

Second, the experimental principle

Under the action of microorganisms, bio-based materials consume oxygen to decompose to produce inorganic substances such as carbon dioxide and water, and the carbon dioxide produced is monitored in real time by high-precision infrared sensors. The percentage of the actual CO2 release of the sample to the theoretical CO2 release of the sample is the biodegradation rate.

When the test is finished, it can be used to determine the degree of disintegration of the experimental material, and also to determine the mass loss of the experimental material.

3. Experimental materials

1. Distilled water

2. Rotten compost (3-4 months of fertilizer age, provided by Tomergen Biotechnology)

3. Thin layer chromatography grade (TLC) cellulose

4, 5mol sodium hydroxide solution

5, 2mol dilute sulfuric acid solution

6. Color-changing silicone

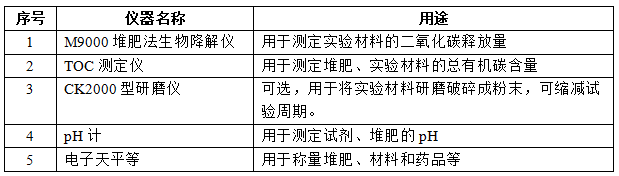

4. Experimental instruments

5. Experimental steps

1. Prepare compost

Weigh a sufficient amount of compost produced by Tomergen Bio, compost age is 3-4 months of rotten compost, humidity is 55%-60%, pH is between 7.0-9.0.

2. Prepare experimental materials and reference materials

Experimental materials can be available in granular, powder, film, or simple shapes (e.g. dumbbells). The maximum surface area of each specimen is approximately 2 cm×2 cm If the original specimen exceeds this size, it should be reduced, or a grinder can be used to grind the specimen into powder for testing.

Thin layer chromatography grade (TLC) cellulose was used as the positively controlled reference material with a particle size of less than 20 μm.

3. Start the experiment

3.1 Turn on the power supply of M9000, set the temperature to 58°C, turn on the internal circulation, and start heating;

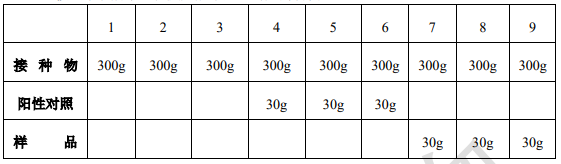

3.2 Add the corresponding substance to the reaction flask as shown in the table below.

Note: The volume of the reaction bottle is 3L; The mixture accounts for about 3/4 of the volume of the reaction vial.

3.3 Add 9ml of 400mol/L sodium hydroxide solution to each of the 5 decarburization bottles;

3.4 Add 9ml of 200mol/L dilute sulfuric acid solution to 2 ammonia removal bottles;

3.5 Place the reaction bottle, decarburization bottle and ammonia removal bottle in the corresponding card slot points, fix them, and then connect the test system with a silicone hose;

3.6 Open the host and computer to record data;

3.7 Turn on oxygen ventilation, adjust the gas flow meter, and set the gas flow rate at 100-200ml/L;

3.8 The test period shall not exceed 6 months, and if significant biodecomposition can also be observed, the test period shall be extended to a constant stationary phase.

4. End the experiment

4.1 If the mass loss of the experimental material is to be determined, weigh the mass of the test mixture in each reaction vial;

4.2 Remove the test mixture from each reaction flask to determine total dry solids and volatile solids;

4.3 Record the details of visual observations of the properties of experimental materials to determine the degree of disintegration.

5. Validity of results

5.1 After 45 days, the percentage of biodecomposition of the reference material exceeded 70%;

5.2 At the end of the experiment, the relative deviation between the biodecomposition percentages of each reaction system in each group did not exceed 20%;

5.3 Inoculum in blank containers yields 10 mg CO50/g volatile solids (average) to 2 mg CO150/g volatile solids (average) 2 days prior to the experiment.

6. Calculation of results

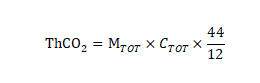

1. Calculate the theoretical release of carbon dioxide

The theoretical carbon dioxide release (ThCO2) of the experimental material is calculated according to the following formula, expressed in (g):

In the formula:

MTOT represents the total dry solid of the experimental material added to the reaction flask at the beginning of the experiment in units (g)

CTOT represents the ratio of total organic carbon to total dry solids in the experimental material in grams per gram (g/g)

44 and 12 indicate the molecular weight of carbon dioxide and the atomic weight of carbon, respectively

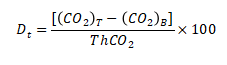

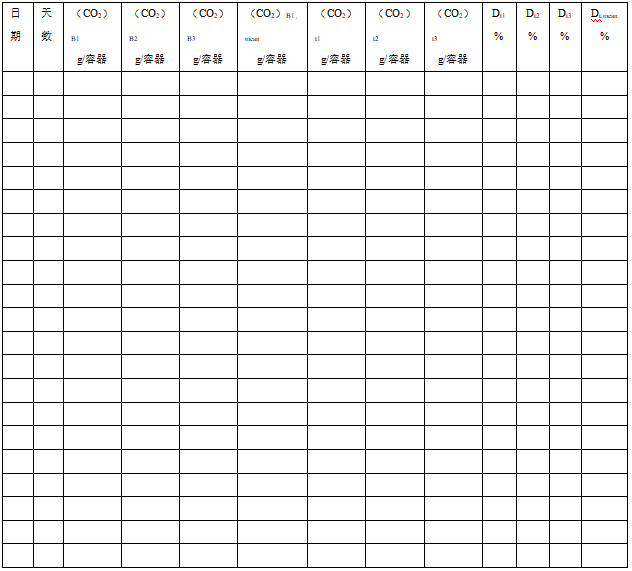

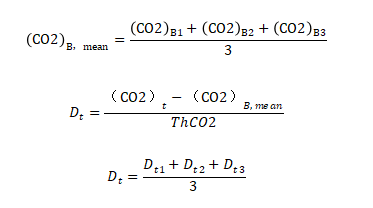

2. Calculate the percentage of biological decomposition

The biodecomposition percentage DT(%) of the experimental materials was calculated according to the cumulative amount of carbon dioxide released in each test cycle.

In the formula:

(CO2)T represents the cumulative amount of carbon dioxide released per vial containing the experimental mixture in grams per container (g/container)

(CO2)T represents the average of the cumulative amount of carbon dioxide released in blank containers in grams per container (g/container)

ThCO2 represents the theoretical amount of carbon dioxide produced by the experimental material in grams per container (g/container)

If the relative deviation of each outcome is less than 20%, the average biodecomposition percentage is calculated, otherwise, the values of each reaction flask are used separately.

The biodecomposition rate of the reference material was calculated using the same method.

3. Calculate quality loss

According to the volatile solids content, the mass loss is calculated according to Annex C of GB/T 19277.1.

7. Experimental report

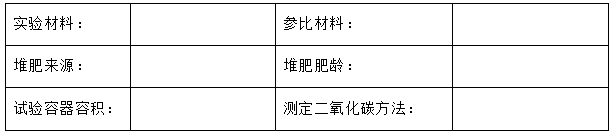

Material degradation experiment report

Experimental results:

Validity judgment basis:

Is the percentage of biodecomposition of the reference material > 45% after 70 days?

□Yes □No

Is the relative deviation in the percentage of biodecomposition of the reference material in different containers < 20% at the end of the test?

□Yes □No

Is the average amount of CO10 produced by the blank container within 50 days before the test between 2 mg CO150/g volatile solids and 2 mg CO<>/g volatile solids?

□Yes □No

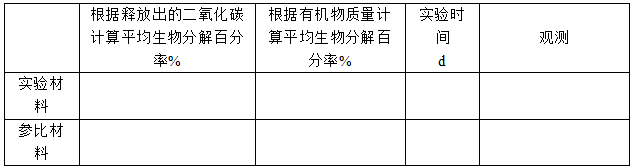

Percentage of biodecomposition calculated based on the amount of carbon dioxide released

Experimental material or reference material: TOC: g/g ThCO2: g/container

(CO2)B – the cumulative amount of carbon dioxide produced by the measured blank test;

(CO2)t – the cumulative amount of carbon dioxide produced by the test material or reference material measured in t time.

Compute:

Percentage of biological decomposition calculated based on mass loss of organic matter

Experimental material: Reference material:

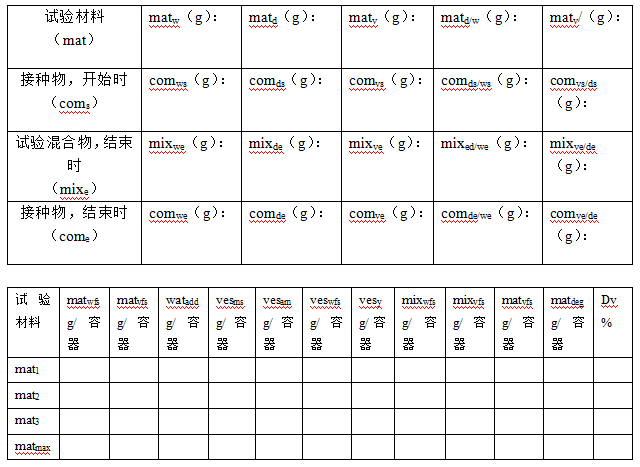

Abbreviations: com = inoculum, mat = test material, mix = test mixture of test material and inoculum, ves = test container, wat = water

Subscript: W = wet material, d = total dry solids, v = volatile solids, d/w = ratio of total dry solids to wet material mass, v/d = ratio of volatile solids to total dry solids, deg = decomposed test material, f = experimental container, s = start of test, e = end of test, y = empty test container (empty weight), a = increased inspection, add = water added, B = blank (inoculum only), m = mixture of test material and inoculum, mean = average. The biological decomposition rate is calculated according to volatile solids: Dv=matdeg×100/matvfs