Nucleic acid extraction sample pre-treatment

Nucleic acid extraction sample pre-treatment

1. Product features:

1. With national invention patent: ZL 2011 1 0168356.2, through CE certification;

2. Vertical oscillation: large stability, complete sample breakage;

3. High efficiency: sample crushing within 2 minutes;

4. High throughput: up to 2×96 samples at a time;

5. Large processing capacity: 2×50ml steel can crush large volumes of samples;

6. Wide range of adapters: 2×96×2ml adapter, 2×48×2ml adapter, 2×24×5ml adapter, 2×10×7ml adapter can be freely selected;

7. High security: with safety door and safety lock;

8. No cross-contamination: the sample tube is fully enclosed during the crushing process to avoid cross-contamination;

9. Low noise: During the operation of the instrument, the noise is less than 70dB, which will not interfere with other experiments or instruments.

II. Product Usage:

1. Suitable for grinding and crushing of various plant tissues including roots, stems, leaves, flowers, fruits, seeds and other samples;

2. Suitable for grinding and crushing of various animal tissues including brain, heart, lung, stomach, liver, thymus, kidney, intestine, lymph nodes, muscle, bone and other samples;

3. Suitable for grinding and crushing of fungi, bacteria and other samples;

4. Suitable for grinding and crushing of food and pharmaceutical component analysis and testing;

5. Suitable for grinding and crushing volatile samples including coal, oil shale, wax products and other samples;

6. Suitable for grinding and crushing of plastics, polymers including PE, PS, textiles, resins and other samples.

Third, the product principle:

Vertical oscillation, the high-frequency reciprocating motion of the oscillation system, so that the frozen sample in the grinding tube collides with the grinding ball, and the grinding shear and impact forces generated by it completely break the tissue.

IV. Technical Parameters:

1. Vertical oscillation;

2. Oscillation frequency: 500-1800 times/min;

3. Grinding time: 10 seconds-99 minutes, user can set by himself;

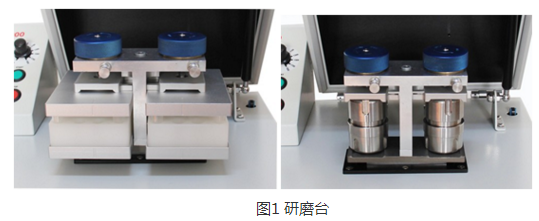

4. Number of grinding platforms: 2;

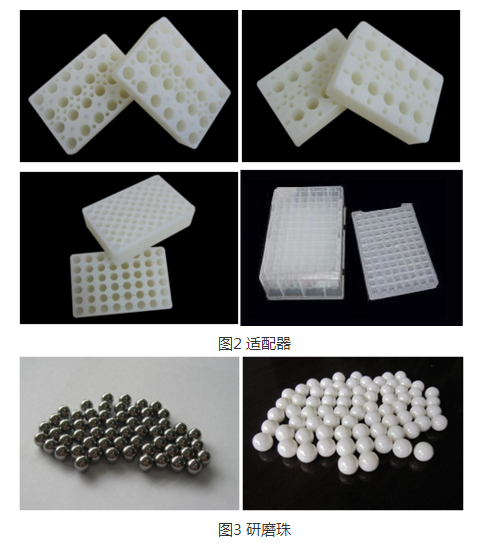

5. Grinding ball material: stainless steel, chromium steel, zirconia, tungsten carbide, quartz sand;

6. Grinding ball diameter: 0.5-30mm;

7. Clamp stroke 3.7cm (vertical);

8. The adapter is resistant to low temperature and can be soaked in liquid nitrogen for more than 30 minutes;

9. Open the door and power off function to ensure safety;

10. Power: 400W;

11. Power supply: 3-pin socket, 220-240V, 50Hz;

12. Weight: 62kg;

13. 尺寸:38cm(W)×46cm(D)×50cm(H)。

V. Configuration:

1. One host;

2. Adapter:

2.1 48-well 2ml adapter 1 pair;

2.2 24/10-well 5/7ml adapter 1 pair (optional);

2.3 50ml grinding jar 1 pair (optional);

2.4 96-well 2ml adapter 1 pair (optional consumables).

3. One set of alloy fixture;

4. One set of grinding balls.

VI. Operation Steps:

1. Add the processed sample and grinding ball to the centrifuge tube in turn;

2. Place the centrifuge tube with the sample into the adapter;

Freeze the adapter with the sample in liquid nitrogen for several minutes;

4. Place the frozen sample and adapter in the middle of the fixture and adjust the position;

5. Place the fixture on the sample stage, position the positioning groove, tighten the vertical positioning knob, and return the safety lock;

6. Close the safety door of the machine;

7. Set the vibration frequency and vibration time;

8. Start the machine and perform the crushing process;

9. Wait for the machine to completely stop vibrating and turn it off, open the safety door, and take out the sample;

10. Instrument homing.

VII. Precautions:

1. The instrument should be placed in a dry and ventilated environment;

2. The sample is symmetrically distributed in the sample holder to ensure the balance of the sample holder;

3. Before closing the safety door, confirm that the fixture is completely fixed and there is no loosening phenomenon;

4. When setting the oscillation frequency, it shall not exceed the maximum range of 1800 times/min;

5. When freezing samples, care should be taken to prevent liquid nitrogen from splashing out and causing frostbite.

Focus on us

-

Beijing Thmorgan Biotechnology Co., Ltd

Telephone:4000-688-151

-

Mailbox:info@thmorgan.com

Address:2711, building 2, Beijing big data intelligent industrial park, 6 Liye Road, Huilongguan town, Changping District, Beijing