Product

All categories

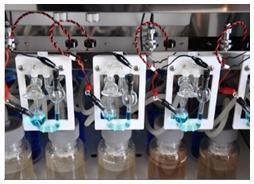

Seawater biodegradation instrument

Model:T9000C

Product use:

1. Can be used for bio-based biodegradability detection, meet GB/T19276-1;

2. Can be used for Marine biodegradability detection,GB/T40611-2011;

3. It can be used for the potential biodecomposition test of materials under the action of specific microorganisms, GB/T 19275-2003;

4. It can be used for biodegradability detection of degradable polyethylene film for packaging, GB/T 2461-1999;

5. Can be used for rapid biodegradability detection of chemicals, GB/T 21801, GB/T 21802, GB/T 21803;

6. Meet international standards OECD301C, OECD301F, OECD302C, EC-partc4, IS05815-1:2003, etc.;

7. Meet international standards OECD, EEC, ASTM, BBA, ISO, MITI test research;

8. Can be used for BOD3, BOD5, BOD7, BOD28, BOD42 and other determination;

9. Can be used for activated sludge biodegradation detection;

10. Can be used for microbial respiration measurement;

Product features:

1. Determine the actual oxygen consumption of the sample by charge movement;

2. No need to dilute the sample: the maximum detection limit can reach 10000 mg;

3. Continuous electrolytic oxygen supply: each bottle of electrolyte can provide several years of electrolytic oxygen. After the electrolyte is used up, it can be used after adding new electrolyte;

4. Precision temperature control:Water bath temperature control, temperature setting range 5-99 ℃, temperature adjustment accuracy ± 0.1 ℃;

5. Number of channels: each instrument includes 9 detection channels;

6. Magnetic mixing system: provide long-term mixing;

7. Data output system: use special software for computer processing, LCD display;

8. Automatic liquid level control: it can replenish water by itself to prevent dry burning;

Product principle:

Microorganisms consume oxygen in the culture bottle, produce carbon dioxide, carbon dioxide is absorbed by quicklime, the pressure of the culture bottle is reduced, so that the pressure on both sides of the pressure gauge produces a pressure difference, resulting in the electrolytic circuit connection, the copper sulfate solution in the electrolytic bottle electrolysis produces oxygen, which is added to the culture bottle, so that the pressure in the culture bottle gradually returns to the initial level. The amount of electricity passed into the electrolytic bottle is proportional to the amount of oxygen produced, and the coulombmeter accurately monitors the amount of electricity passed into the electrolytic bottle, so as to calculate the oxygen consumption. The ratio of actual and theoretical oxygen consumption is the biodegradation rate of the test sample.

Technical parameters:

1. Working conditions:

1.1 Power supply voltage: AC 220V±10% 50Hz single-phase;

1.2 Working temperature: 15 ~ 30℃;

1.3 Relative humidity: ≤ 80%;

2. Oxygen supply system

2.1 Oxygen supply mode: closed copper sulfate electrolytic oxygen supply;

2.2 Electrolytic bottle internal liquid: saturated copper sulfate solution;

2.3 Opening and closing of electrolysis: the air pressure on both sides of the U-tube;

2.4 Electrolytic accuracy: sensitivity 9.806Pa, the interior is saturated copper sulfate solution;

2.5 Electrode: platinum (positive), copper (negative);

2.6 Electrolytic bottle material: high borosilicate hard glass;

3. Temperature control system:

3.1 Temperature control mode: water bath;

3.2 Set temperature range: 4-99℃, step by 0.1℃;

3.3 Temperature accuracy: ≤±0.1℃;

4. Reaction system

4.1 Reaction mode: liquid reaction;

4.2 Reaction system: closed electrolytic reaction;

4.3 Mixing mode: 9-channel magnetic mixing;

4.4 The volume of the culture bottle is 500ml.

4.5 Decarbonization system: none;

4.6 Condensing System: None.

5. Test the system

5.1 Detection principle: Coulomb meter method to detect charge movement, 4 charges corresponding to an oxygen molecule;

5.2 Detection accuracy: ≤ 0.2ppm;

5.3 Measuring range: 0-10000 ppm;

6. Software control system

6.1 Software control system with independent intellectual property rights;

6.2 Software can collect data and generate real-time data curve;

6.3 Bearer system: professional operating system such as win7/8/10;

6.4 Data storage: It can be stored in real time in the experiment;

6.5 With a cloud platform, data can be accessed remotely;

6.6 USB ports: 3.

Standard configuration

|

erial number |

name |

quantity |

unit |

remark |

|

1 |

host |

1 |

Taiwan |

|

|

2 |

Reaction flask |

9 |

entries |

|

|

3 |

Decarburization bottle |

9 |

entries |

|

|

4 |

Condensing bottle |

9 |

entries |

|

|

5 |

Dehumidifier bottle |

9 |

entries |

|

|

6 |

Connecting hose |

1 |

Set of |

|

|

7 |

software |

1 |

Set of |

|

|

8 |

Rando |

1 |

Set of |

|

Typical cases

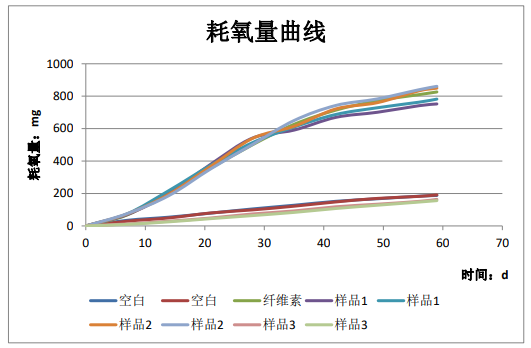

This is the experimental result of determining the biodegradability of a sample by using the T9000 hydroponic biodegradation instrument and referring to the method standard of GB/T19276.1-2003. The test period is 59 days. At the end of the test, the degradation rate of cellulose is 89.53%, and the curve of various product groups is flat, and the growth is basically over. The experimental design and experimental results are as follows:

Table 1 Experimental design

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

Inoculum |

300ml |

300ml |

300ml |

300ml |

300ml |

300ml |

300ml |

300ml |

300ml |

|

cellulose |

|

|

600mg |

|

|

|

|

|

|

|

Sample 1 |

|

|

|

600mg |

600mg |

|

|

|

|

|

Sample 2 |

|

|

|

|

|

600mg |

600mg |

|

|

|

Sample 3 |

|

|

|

|

|

|

|

600mg |

600mg |

Figure 1 Oxygen consumption curve