Product

All categories

Seawater biodegradation instrument

Model:OM7000A

Product use:

1. It can be used for biological degradation detection by activated sludge method, meeting GB/T19276-1;

2. It can be used for soil method biodegradation detection, meeting GB/T22047-2008;

3. It can be used to detect the biodegradability of plastics in seawater/sandy sediment, ISO 18830;

4. Meet international standards ISO 14851 and ISO 17556;

5. Rapid biodegradability test of chemicals, GB/T 21801, GB/T 21802, GB/T 21803;

6. Meet OECD301C, OECD301F, OECD302C, EC-partc4, IS05815-1:2003;

7. Meet OECD, EEC, ASTM, BBA, ISO and MITI test research;

8. It can be used for the determination of BOD3, BOD5, BOD7, BOD28, BOD42, etc;

9. Microbial respiration test;

10. Microbial breeding test;

Product features:

1. The detection system is accurate: measure the oxygen consumed by electrical signals;

2. No need to dilute the sample: the maximum detection limit can reach 1000 ppm;

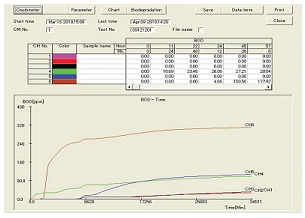

3. Data processing software: a set of software can control 8 devices to work at the same time;

4. Continuous electrolytic oxygen supply: after the electrolyte is used up, add new copper sulfate electrolyte to use;

5. Precision temperature control: the temperature setting range is 5-40 ℃, and the temperature adjustment accuracy is ± 0.1 ℃;

6. Number of channels: each instrument includes 6 detection channels;

7. Two-way mixing system: mixing speed, time and direction can be set by yourself;

8. Dual data output system: special software computer processing, LCD display.

Product principle:

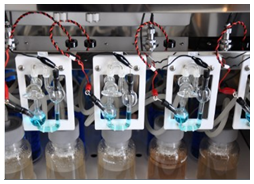

The microorganism consumes the oxygen in the culture bottle, produces carbon dioxide, and the carbon dioxide is absorbed by quicklime. The pressure of the culture bottle decreases, causing a pressure difference on both sides of the pressure gauge, resulting in the connection of the electrolytic circuit. The copper sulfate solution in the electrolytic bottle electrolyzes to produce oxygen, which is added to the culture bottle, so that the pressure in the culture bottle gradually recovers to the initial level. The quantity of electricity fed into the electrolytic bottle is proportional to the oxygen produced. The coulomb meter accurately monitors the quantity of electricity fed into the electrolytic bottle, thus calculating the oxygen consumption. The ratio of the actual oxygen consumption to the theoretical oxygen consumption is the biodegradation rate of the test sample.

|

|

Technical parameters:

1. Continuous dynamic oxygen supply system

1.1 Channels: at most 6 channels are tested at the same time;

1.2 Oxygen supply mode: generate oxygen by electrolytic copper sulfate;

1.3 Electrolytic bottle internal solution: copper sulfate solution;

1.4 Pressure gauge: sensitivity 9.806 Pa, internal copper sulfate solution;

1.5 Mounting frame material: propylene;

1.6 Electrolytic bottle: capacity 500 ml, material: hard glass;

1.7 Electrode: platinum (positive), copper (negative);

1.8 Culture flask: capacity 500 ml (for 300 ml sample culture), material: hard glass;

1.9 Air bottle material: hard glass;

1.10 Mixer material: fluorinated resin;

2. Constant temperature cultivation system

2.1 Set temperature range: 5-40 ℃, step 0.1 ℃;

2.2 Temperature accuracy: ± 0.1 ℃;

2.3 Control mode: SSR drive, ON/OFF control;

2.4 Environmental conditions: 5-30 ℃, 35-85% RH;

2.5 Temperature regulator: digital temperature controller EC5502R00020, - 150 ℃~150 ℃, Pt100;

2.6 Refrigerator: 2500W reciprocating moving refrigerator;

2.7 Safety device: hydraulic thermostat (the set temperature of the anti-overheating device is about 60 ℃);

2.8 Refrigerator protection: overload relay, automatic recovery pressure switch;

3. Magnetic stirring system

3.1 Voltage: 100 V; Power: 3 w;

3.2 Standard specification: clockwise rotation, speed: 540 rpm (50 Hz)/650 rpm (60 Hz);

3.3 Option 1: clockwise rotation; Speed: 70-800 rpm adjustable;

3.4 Option 2: bidirectional rotation; Speed: 540 rpm (50 Hz)/650 rpm (60 Hz);

4. Detection system

4.1 The measurement is more accurate by detecting the charge movement and converting it into oxygen consumption;

4.2 Sensitivity: 0.2 ppm;

4.3 Measurement range: 0-1000 ppm;

4.4 Temperature probe: Pt100;

4.5 Alarm output: 2-point output, contact capacity, 3A/250VAC, 3A/30VDC;

4.6 Alarm function: abnormal electrolytic current, abnormal integral speed, continuous ON/OFF alarm of pressure gauge;

4.7 Communication: Ethernet, transmission type: 10BASE-T;

5. Software control system

5.1 Software control system with independent property rights;

5.2 The software is connected to the host through the unique ARCNET device;

5.3 A set of software can control up to 8 devices at the same time;

5.4 The software collects data and generates real-time data curve.

Standard configuration:

1. One host;

2. One set of continuous oxygen supply device;

3. A set of software.