Product

All categories

Anaerobic reaction biodegrader

Model:CH1200

Instrument use:

1. Meet the testing requirements of ASTM D5511.13526 standard;

2. Used for anaerobic reaction biodegradation experimental research;

3. For the detection of biodegradation rate of biobased anaerobic reaction;

4. For renewable bioenergy research;

5. Used for anaerobic reaction biodegradation process analysis;

Product characteristics

1.Nitrogen generator supply nitrogen;

2.The design method of solid culture and open gas supply is adopted;

3.High detection accuracy,12 independent methane detection, real-time online measurement of methane release;

4.Dual display of methane concentration and accumulation, which can be derived in the form of charts or curves;

5.Wide detection range, the highest detection limit can reach 10000ppm;

6.Silent design,12 independent controllable gas supply, sound less than 45db;

7.Automatic mixing, automatic water, automatic control;

8.Double-layer reactor design is more conducive to gas supply and humidity regulation;

9.Cloud platform detection, real-time online observation of data and curves.

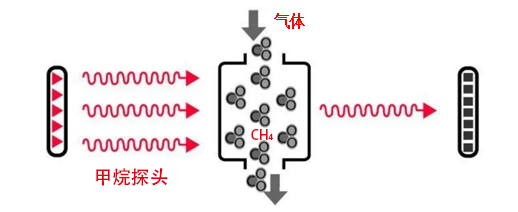

Product principle:

Bio-based materials are metabolized by anaerobic microorganisms under appropriate temperature and humidity under anaerobic conditions, resulting in anaerobic biodegradation of samples to produce methane and other final products. The ratio of methane generation to theoretical generation through whole-process detection is the biodegradation rate of anaerobic reaction.

Technical parameters:

1.Working conditions:

1.1 Power supply voltage: AC 220V±10% 50Hz ;

1.2 Working temperature:15~30℃;

1.3 Relative humidity:≤80%;

2.Air supply system

2.1 Gas supply mode: nitrogen generator for 99.9% pure ammonia gas;

2.2 Air pump control: the air pump is divided into 12 channels, each channel has an independent switch;

2.3 Electronic flowmeter adjustment range: 0.01-500ml /min;

2.4 Adjustment range of glass rotameter: 50-300ml/min;

2.5 With 12 glass rotameters to adjust the flow rate;

2.6 With 12 electronic flowmeters to collect flow rate;

3.Temperature control system:

3.1 Temperature control mode: air bath;

3.2 Set temperature range: room temperature -90℃, step by 0.1℃;

3.3 Temperature control accuracy: <±0.1℃;

3.4 Temperature control box top sliding door, easy to operate;

4.Reactor system:

4.1 Number of channels:12;

4.2 Reactor volume: 2000ml;

4.3 Reactor design: double-layer design;

4.4 Adding water: manually adding water;

4.5 Mixing method: manual mixing;

4.6 Mixing shaft design: mixing down;

4.7 Gas supply mode: bottom gas supply;

5.Test the system

5.1 Detection method: methane probe to detect methane;

5.2 Number of methane probes: 12;

5.3 Display mode: synchronous dual display of methane concentration and total quantity;

5.4 Detection range :0-10000ppm;

5.5 Resolution:1ppm;

5.6 Data collection cycle: up to 1 second once, seconds, minutes, hours can be freely selected;

5.7 Probe dehumidification protection system: Yes;

6.Software system

6.1 Software control system with independent intellectual property rights;

6.2 Software can collect data and generate real-time data curve;

6.3 Bearer system: professional operating system such as win7/8/10;

6.4 Data storage: It can be stored in real time in the experiment;

6.5 With a cloud platform, data can be accessed remotely;

Instrument configuration requirements

|

serial number |

name |

quantity |

unit |

remark |

|

1 |

host |

1 |

台 |

|

|

2 |

reaction bulb |

12 |

个 |

|

|

3 |

Decarburization bottle |

12 |

个 |

|

|

4 |

condensing bulb |

12 |

个 |

|

|

5 |

Dehumidifier bottle |

12 |

个 |

|

|

6 |

connection hose |

1 |

套 |

|

|

7 |

software |

1 |

套 |

|

|

8 |

random file |

1 |

套 |

|